#TEXTILE INDUSTRY

Explore tagged Tumblr posts

Text

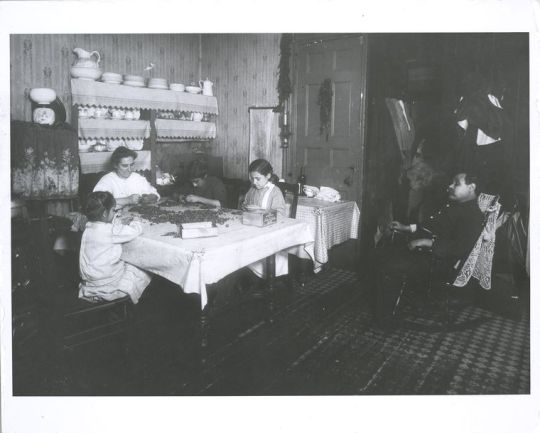

Women and children sewing, doing piece work, at home and in sweatshops, early 20th century.

From New York Public Library Archives

31 notes

·

View notes

Text

youtube

Every year, nearly 100 billion items of clothing are produced – and 65% of them end up in a landfill within 12 months. New technologies in textile recycling may be able to curb that waste – while producing a host of sustainable materials.

#planeta #recycling #fastfashion #circulareconomy #textileindustry

We're destroying our environment at an alarming rate. But it doesn't need to be this way. Our new channel Planet A explores the shift towards an eco-friendly world — and challenges our ideas about what dealing with climate change means. We look at the big and the small: What we can do and how the system needs to change. Every Friday we'll take a truly global look at how to get us out of this mess.

Follow Planet A on TikTok: https://www.tiktok.com/@dw_planeta?la...

Credits:

Report: Dave Braneck

Video Editor: Frederik Willmann

Supervising Editor: Michael Trobridge

Fact Check: Alexander Paquet

Thumbnail: Ém Chabridon

Read More:

McKinsey - Scaling Textile Recycling in Europe

https://www.mckinsey.com/industries/r...

NY Times - Will We Ever Be Able to Recycle Our Clothes Like an Aluminum Can?

https://www.nytimes.com/2022/11/30/st...

EU Strategy for Sustainable and Circular Textiles https://environment.ec.europa.eu/stra...

Chapters:

00:00 Intro

00:46 Textile waste's global impact

02:47 How do you actually recycle clothes?

03:50 New approaches to textile recycling

07:41 What else needs solving?

11:41 Can we even recycle all the clothes we make?

#DW Planet A#solarpunk#fashion#fashion industry#fast fashion#fashion waste#circular fashion#recycling#textiles#textile industry#sustainable fashion#sustainable textiles#textile recycling#Youtube

7 notes

·

View notes

Text

Bronica ETRS with Zenzanon 50mm f2.8 lens, shot on Kentmere 100 and developed with Ilford Ilfosol 3

#photography#film photography#ishootfilm#analog photography#filmisnotdead#b&w photography#120 film#medium format#textile industry#industrial#industrial photography#textiles#bronica etrs#bronica#kentmere pan 100

5 notes

·

View notes

Video

Band Collar Shirts by Katsuaki Shoda

#Kobe#Hyogo#Japan#Front View#Fashion#No People#Template#Vector#Textile Industry#Classical Style#Group Of Objects#flickr

2 notes

·

View notes

Text

Textile day; cotton gin, loom, and spinning wheel.

#photography#my photography#cotton gin#loom#spinning wheel#textile industry#not my usual subjects but still very neat

4 notes

·

View notes

Text

Conservation Misconceptions

In trying to be environmentally conscious, many people struggle to find ways to really make a difference. This makes misinformation easy to fall for, especially when it leaves out the nuance of trying to be environmentally friendly.

Leather

“Vegan clothing” reached popularity as early as the 1970s. Its sleek, shiny, and stretchy look make it ideal for many fashion icons. In November of 2023, reality TV star Kylie Jenner released a line of twelve “faux leather” or ‘pleather’ outfits. In the first hour, it had reached one million dollars in sales.

The appeal of vegan clothing is understandable. Many people in the U.S. hear about the horrors of the cattle industry before entering high school. Many people sympathize with animals and seek ways to reduce their consumption of animal products.

Contradictorily, faux leather is significantly harmful to the environment. Most pleather consists of polyurethane, which is plastic. It is unsustainable on the basic factor of the oil from which it originates being nonrenewable. Additionally, manufacturing this material includes high levels of toxic chemicals like dimethylformamide which is linked to cancers and birth defects. Polyurethane pleather can also take one thousand years to break down in a landfill.

Leather, from the hides of cow, sheep, goat, deer, and many other animals, is organic. It breaks down at the end of its life, usually over ten to fifty years in landfills.

Interestingly, plastic clothing in a landfill takes a long time to degrade while leather breaks down quicker. Yet during its use, plastic is prone to scuffs, tears, and showing more wear while leather clothing can last years without significant damage.

Leather is not all perfect, of course. Animal cruelty is a large factor for people turning to faux leather, and those concerns are well-founded. Animal cruelty in the leather and meat industries is well-evidenced.

Aside from animal cruelty, tanning hides also produces chemical contamination. While chromium used in leather tanning is less toxic now than earlier solutions, it is still hazardous. Other hazardous materials in leather tanning include nitrosamines, benzidine-based dyes, and formaldehyde. Being exposed to the former two in high levels can increase the risk of cancers, while formaldehyde causes skin irritation, nausea, and respiratory difficulties.

Addressing fashion industry pollution is not as easy as switching entirely to different materials. A more effective alternative to fake leather is addressing the waste of the fashion industry. In 2023, the fashion industry produced 97 million tons of waste, including 18 million tons from textiles and 2.5 million tons in chemical waste.

Additionally, there are vegan clothing options from plant alternatives. One example, calotropis, is sometimes considered wool without the need for sheep. Calotropis plants grown in India need little in regard to water, attention, and pesticides. Cactus leather is another example which requires less water and produces less plastic. When industries turn to plants, the supply chain and issues of fair trade continue to require attention, but these avenues of sustainability are possible.

Turning to leather entirely is not the ideal choice while the farming industry retains its wealth of problems, but pleather is not a suitable replacement. Those seeking to be environmentally conscientious with clothing choices can try non-synthetic materials like colatropis, cactus leather, and linen.

Honey

Veganism is a diet people adopt for a variety of reasons. Some have biological restrictions that a vegan diet works best with, helping them to avoid foods they can’t eat. Others do it in an effort to consume fewer calories, and some use it in an effort to reduce the waste and mistreatment in the farming industry.

In a strict vegan diet, one avoids all animal products, usually summed up as milk and eggs. Strictly speaking, honey would be included in those animal products. But for those eating a vegan diet for ethical reasons, avoiding honey can do more harm than good.

Honey alternatives include maple syrup, molasses, and more. Maple syrup and molasses contain important nutrients, but some dieters find them to contain too much sugar.

Another popular honey alternative, with lower amounts of sugar, is agave syrup. Agave syrup also contains vitamins and other nutrients, and comes from the agave plant, which is grown around the world but native to Mexico and the southwest U.S.A.

Agave farming faces multiple problems. One is that agave plants are fragile, and will have trouble surviving in the rapid climate changes the world is experiencing. While agave does well in desert conditions, climate change might cause desert-like conditions for some months or some years and without warning flip in the opposite direction. Similarly, demand for agave is growing but could shift rapidly. For a plant that can take seven years to grow before harvesting, farmers can have a difficult time planning their supply in a way that’s sustainable to them and consumers.

Agave is also often grown as a monocrop, which is unsustainable for long-term agriculture, and carries risks of run-off, blight, and increased need for fertilizers and pesticides. Harvesting blue agave specifically also depletes a vital food resource for the lesser-nosed bat species.

Perhaps the most important consideration with agave plants is the inequity associated with it. Slave labor, underpaid labor, and child labour are dire problems across the agricultural industry. Fair trade certification exists for some agave-related brands, but cannot be assured for all of them. In 2021, data from the Brazilian Institute of Geography and Statistics registered 1.8 million children involved in child labor, with 45.9 percent of them in the occupations of operating agricultural machinery, and of processing tobacco, agave, and sugar cane.

Ethical alternatives to honey are not necessary. Responsible beekeeping hurts no honeybees. It is a symbiotic relationship. Bees gain protection and a good hive place, with the freedom to leave if conditions are poor. Beekeepers harvest excess honey that the hive does not need to sustain itself. It is a sustainable, beneficial practice that produces a sweetener which very few humans are allergic to.

Alternatives to products we use in our daily lives can become trendy and take some time to see the true impact of. While vying for a more environmentally friendly life, we can be misled or mistaken about the true sustainability of products. It is important to continue to learn about and educate ourselves on the products we’re using.

Additional Resources

1. Faux Leather Unsustainability

2. Fashion Industry Waste

3. Sustainability of Leather

4. Comparing Leather and Faux Leather

5. Problems with Leather

6. Ethics and Fashion

7.Vegan_leather_An_eco-friendly_material_for_sustainable_fashion_towards_environmental_awareness

8. Leather Tanning

9. Plant-based Alternatives

10. Agave Climate Change

11. Agave and Bats

12. Beekeeping Sustainability

#environment#climate change#resources#research#article#renewable energy#sustainability#faux leather#pleather#leather#textile industry#honey#beekeeping#farming#child labor#anti capitalism

2 notes

·

View notes

Text

Fast fashion wants to produce fast. So, the garment worker has to produce faster. And cheap. The garment worker is the only point of the supply chain where the margin is squeezed...But also, from the consumer point of view, is it really democratic to buy a t-shirt for $5 and a pair of jeans for $20? Or are they taking us for a ride? Because they are making us believe that we are rich or wealthy because we can buy a lot. But, in fact, they're making us poorer. And the only person who is becoming richer is the owner of the fast fashion brand.

- Livia Firth in The True Cost - The Truth of the Clothing Industry

#q#quotes#livia firth#the true cost#mindful consumption#mindful living#mindfulness#fashion industry#fast fashion#textile industry#haute couture#ethical consumption#holistic healing#earth stewardship#exploited workers#holistic leveling up#leveling up#green juice girl#that girl#sustainability#green living#consumerism#ethical clothing#sidewalkchemistry

17 notes

·

View notes

Text

I know "there's no ethical consumption under capitalism" has become an excuse instead of something that should radicalize you, but it's incredibly infuriating that I can't even buy a pack of new underwear from the one brand that doesn't give me an allergic reaction from their elastic without worrying I'm funding the exploitation of child migrant "workers" in their U.S factories, and does it even matter because almost every other cheap underwear brand most likely is manufactured in factories overseas that are equally exploiting children and their labor force as a whole

4 notes

·

View notes

Text

Unsold clothing may no longer be destroyed in Europe

More than 100,000 tons of discarded clothing ends up in a desert in Chile

Europe is putting a stop to the throw-away culture through a ban on destruction[1] and a digital product passport with information about shelf life and repairability. No more mass destruction of clothing and other unsold merchandise.[2]

Every second in Europe, a full garbage truck of clothing is burned or dumped[3]. And every year, an estimated 11 to 32 million unsold and returned garments are destroyed. Europe has been wanting to reduce this gigantic waste for some time. The European Member States and the European Parliament reached an agreement to this end on Monday evening 4-12: Ecodesign for Sustainable Products Regulation[4]. The aim of the 'eco design law' is to make many products more repairable, reusable and recyclable. A product passport and a ban on destruction of unused goods are the key measures.

1. What is a digital product passport?

Consumers are already somewhat familiar with this: the energy label on refrigerators and washing machines gives an indication of their sustainability. That label (or product passport) has had an enormous impact on making those appliances more energy efficient.

The European Parliament and the EU member states now have an agreement to roll out the digital passport more widely and to deepen its content. First of all, almost all products on the European market will have to have such a passport: from car tires and steel to washing tablets and cosmetics to clothing or smartphones. The only exceptions are food, medicine, cars and weapon systems, for which there are separate regulations.

In addition to any energy consumption, the passport also contains information about the origin, composition, repair and disassembly options of the product. This should also make it easier to repair and recycle them. “People can know at a glance which product is the most durable or easiest to repair,” said MEP Sara Matthieu (Green), who was rapporteur in the negotiations.

2. What does the ban on destruction mean?

Initially, the ban applies to textiles. Globally, 92 million tons of textile waste are produced annually. A large portion of these are returned or unsold goods. In two years' time, they may no longer be destroyed, but must be reused or recycled. This ban will eventually be extended to electronics and electrical appliances. Massive quantities of these are also destroyed every year, especially cheaper items that are not sold or have been returned to the manufacturer.

The new rule goes hand in hand with stricter requirements for composition, repairability and disassembly of goods. The details will be worked out product by product by the European administration, but some guiding principles are a ban on adhesives, the absence of toxic substances, the obligation to have spare parts available and, above all, to offer them at an affordable price. The passport should eventually lead to a 'repair score', comparable to the energy label.

Matthieu (Green) expects a huge impact on the consumer market. 'Instead of offering disposable products for mass consumption, companies will offer many more services through robust devices. So to speak, you will no longer buy a washing machine, but an number of wash cycles.'

3. How comprehensive are the measures?

That depends on the control. The product passport is also an important instrument for this. Europe is counting on the famous 'Brussels effect': foreign producers will have to adapt their products if they want to maintain access to the gigantic European consumer market. Although the European consumer organisation BEUC[5] warns against loopholes. The organisation mainly sees a risk that international online platforms such as Amazon or Alibaba will circumvent the new law.

4. Is this agreement now final?

It has already rounded the most important cape. The agreement was finalised in the so-called trialogue negotiations between the European Parliament, the European Council and the Commission. Now it must be approved by Parliament and the Member States, but that counts as a formality.

Source

Lieven Sioen, Onverkochte kledij mag niet meer vernietigd worden in Europa, in: De Standaard, 6-12-2023, https://www.standaard.be/cnt/dmf20231205_96579697#:~:text=In%20eerste%20instantie%20is%20het,ze%20hergebruikt%20of%20gerecycleerd%20worden.

[1] Deal on new EU rules to make sustainable products the norm; https://www.europarl.europa.eu/news/en/press-room/20231204IPR15634/deal-on-new-eu-rules-to-make-sustainable-products-the-norm

[2] Read also: https://www.tumblr.com/earaercircular/722179599996534784/towards-a-circular-and-more-sustainable-fashion?source=share

[3] Read also: https://www.tumblr.com/earaercircular/723895455727157248/new-report-clothes-are-mercilessly-downcycled-or?source=share & https://www.tumblr.com/earaercircular/720260226679488512/hms-answer-about-the-dumped-clothes-article?source=share

[4] The proposal for a new Ecodesign for Sustainable Products Regulation (ESPR), published on 30 March 2022, is the cornerstone of the Commission’s approach to more environmentally sustainable and circular products. The proposal builds on the existing Ecodesign Directive, which currently only covers energy-related products. https://commission.europa.eu/energy-climate-change-environment/standards-tools-and-labels/products-labelling-rules-and-requirements/sustainable-products/ecodesign-sustainable-products-regulation_en

[5] The European Consumer Organisation (BEUC, from the French name Bureau Européen des Unions de Consommateurs, "European Bureau of Consumers' Unions") is an umbrella consumers' group, founded in 1962. Based in Brussels, Belgium, it brings together 45 European consumer organisations from 32 countries (EU, EEA and applicant countries). BEUC represents its members and defends the interests of consumers in the decision process of the Institutions of the European Union, acting as the "consumer voice in Europe". BEUC does not deal with consumers’ complaints as it is the role of its national member organisations.

3 notes

·

View notes

Text

Navigating the Threads of Change: Sustainable Textile Practices Transforming the Fashion Industry

In an era of heightened environmental awareness, the textile industry is undergoing a profound transformation, driven by a growing commitment to sustainability. These practices might get started right from the design process. In this article, you’ll learn about some of the practices that are changing the textile industry trends and can bring a revolutionary change.

||Re-thinking Raw Materials: A Shift towards Eco-Friendly Choices||

At the heart of sustainable textile practices lies a re-evaluation of materials used in the production process. Traditional textiles often rely on resource-intensive materials such as conventional cotton, which is notorious for its heavy use of pesticides and water.

Sustainable alternatives, for example, organic cotton, bamboo, and hemp, have emerged as eco-friendly options that minimize the environmental impact. Organic cotton, for instance, is grown without the use of synthetic pesticides or fertilizers, promoting soil health and reducing harm to nearby ecosystems.

||Recycled Materials: Closing the Loop and Reducing Waste||

One noteworthy development in sustainable practices is the rise of recycled materials. Post-consumer waste, including discarded plasticized objects and other textile scraps, is being repurposed to create new products. This not only diverts waste from landfills but also mitigates the demand for new materials, contributing to a more circular and sustainable system.

||Slow Fashion: A Counterbalance to Fast Fashion's Disposable Culture||

Furthermore, these sustainable initiatives are closely tied to the concept of slow fashion. This movement advocates for a shift away from the fast-paced, disposable nature of the industry, encouraging consumers to invest in high-quality, timeless pieces that endure through seasons.

||Revolutionizing Manufacturing: Waterless Dyeing and Plant-Based Alternatives||

Beyond the choice of raw materials, these practices extend to the manufacturing processes employed by many best textile industries. The conventional dyeing and finishing of textiles involve the use of numerous harmful chemicals that not only pose risks to the environment but also to the workers involved in the production process. Therefore, the use of natural alternatives can change the whole scenario of attaining sustainability.

||Current scenario towards sustainability||

Major fashion brands are recognizing the importance of sustainability and are following these principles into their business models. From creating sustainable materials into their collections to adopting transparent and ethical supply chain practices, these top textile companies are driving positive change within the industry.

Yet, the shift towards sustainable textile practices is not without its challenges. The initial costs associated with sustainable materials and processes can be higher, posing financial obstacles for some manufacturers. However, as consumer demand for eco-friendly products continues to rise, economies of scale and increased innovation are expected to drive costs down, making sustainability practices more accessible for all.

||Conclusion||

In conclusion, sustainable textile practices are setting a new narrative for the industry, one that prioritizes environmental stewardship, ethical practices, and long-term viability. The threads of change are being woven into the fabric of fashion, stitching together a more sustainable and conscious future for all.

#textile industry#textile shop near me#textile#textile company in panipat#textile industry in panipat#textile mills in panipat

2 notes

·

View notes

Text

@theprodigalrobot is saying what we’re all needing to hear and me thinks it shouldn’t be hidden in the tags.

This is a huge problem with having industry located far outside of where its consumers actually are and a great way for producing masses of it because /most people would not be ok with what is going on in those factories including how materials are being sourced/. I have an inkling that the US government is relieved that they don’t have to deal with their ‘Merica ass country in fixing labor and sourcing problems (which if we look into the industrial age in America /they would absolutely have to do no matter how much of an uphill battle it is/).

I’m honestly not sure what the next thing to tick off the American public will be, but being that the #1 cause of death is diabetes (despite the productions we have to /source healthy food/) I bet it’ll be related to consumer goods like fresh produce or healthcare. The fact that so many ad campaigns are to “eat healthy to be healthy!” and “exercise is your #1 go-to to lead a long and healthy life!” when the application of health into US students lives is poorly done and honestly a bit unachievable as prices start stacking up is atrocious to me. Eating healthy and exercising /is/ fundamentally important, but health looks different for different people. just like how the average American doesn’t know everything that goes into a single apple or sweatshirt, they don’t know what goes into the things doctors prescribe to them and they don’t have any /real/ knowledge on how to prevent disease or injuries that are simply a testament of life.

It makes me quite unreasonably mad lol

#mass production#food insecurity#food industry#textiles#textile industry#cows#cows have feelings and watch sunsets but they also carry disease B)#healthcare#healthcare industry#american culture#education

56K notes

·

View notes

Text

youtube

Every week, Eco India brings you stories that inspire you to build a cleaner, greener and better tomorrow.

Dye-infused effluent worsens India's water crisis. A fabric workshop and chemical firm in Gujarat have some ideas — from harvesting rainwater to bio-remediation via canna — and using sustainable pigments.

***********

Credits

Supervising Producer: Nooshin Mowla

Field Producer & Script: Aadya Baoni

Video Editor: Richard Kujur Associate Producer: Ipsita Basu

Director of Photography: Paul Varghese

DoP Asst: Vivek Bhaya

Production Assistant & Script: Aakriti Thatal

Executive Producer: Sannuta Raghu

#Scroll.in#eco india#solarpunk#dye#fabric#textile#textile industry#water#water crisis#fabric workshop#Gujarat#india#rainwater#rainwater harvesting#bio-remediation#canna#pigments#sustainable pigments#Youtube

11 notes

·

View notes

Text

Bronica ETRS with Zenzanon 50mm f2.8 lens, shot on Kodak Portra 400

#photography#film photography#ishootfilm#analog photography#filmisnotdead#colour photography#medium format#bronica etrs#etrs#industrial#industrial photography#loom weaving#loom#textile industry#120 film#kodak portra 400

3 notes

·

View notes

Text

Transforming Textiles with Enzymatic Solutions: Pharmabiz.world at the Helm

The textile industry is undergoing a remarkable transformation, driven by innovations that prioritize efficiency, sustainability, and quality. At the heart of this change are enzymes—nature’s catalysts that unlock unparalleled potential in textile processing. Pharmabiz.world, a global leader in enzyme manufacturing, is pioneering the next generation of enzymatic solutions for the textile industry, enabling manufacturers to achieve more with less.

Why Enzymes Are Revolutionizing Textiles

Textile processing involves multiple stages, from pre-treatment and dyeing to finishing. Traditional methods often rely on harsh chemicals, high temperatures, and extensive water usage, which can harm both the environment and the fabric. Enzymes offer a greener, more efficient alternative. These biocatalysts facilitate targeted reactions under mild conditions, delivering superior results with minimal environmental impact.

Pharmabiz.world specializes in creating enzyme formulations tailored for textile applications, empowering manufacturers to:

Improve Fabric Quality: Enzymes gently modify fibers, enhancing texture, strength, and appearance.

Reduce Resource Usage: Lower water, energy, and chemical consumption contribute to cost savings and sustainability.

Minimize Waste: Efficient processes decrease effluents, reducing the environmental footprint.

Pharmabiz.world’s Textile Enzymes: Innovation in Action

Pharmabiz.world’s portfolio of textile enzymes addresses every stage of the production process, ensuring optimal results for diverse materials and applications. Key offerings include:

Desizing Enzymes: Designed to break down starch-based sizing agents, these enzymes simplify pre-treatment, reducing water and energy requirements.

Bio-Scouring Enzymes: Replace harsh chemicals with enzymes that effectively remove impurities, such as pectin and wax, while preserving fiber integrity.

Cellulase Enzymes: Perfect for fabric softening and bio-polishing, these enzymes eliminate surface fuzz and enhance the smoothness and brightness of textiles.

Bleach-Boosting Enzymes: Enable efficient peroxide bleaching at lower temperatures, saving energy and reducing fabric damage.

Dye-Enhancement Enzymes: Improve dye uptake and color vibrancy, ensuring consistent results with reduced chemical inputs.

Benefits of Partnering with Pharmabiz.world

Choosing Pharmabiz.world as your enzyme supplier means more than access to cutting-edge products. It’s a partnership grounded in innovation, expertise, and a commitment to excellence. Benefits include:

Custom Solutions: Tailored enzyme formulations meet the unique requirements of your production processes.

Technical Support: Comprehensive guidance from our expert team ensures seamless integration and maximum efficacy.

Sustainability Leadership: Collaborate with a partner dedicated to reducing the environmental impact of textile production.

Real-World Impact

Manufacturers across the globe have already experienced the transformative effects of Pharmabiz.world’s enzymatic solutions. For example:

A leading denim producer in Europe reduced its water usage by 30% and achieved a 20% increase in production efficiency by switching to bio-polishing enzymes.

An Indian textile mill improved fabric quality and cut chemical costs by 25% with Pharmabiz.world’s bio-scouring enzymes.

Shaping the Future of Textiles

As the textile industry evolves to meet the demands of eco-conscious consumers and regulatory pressures, enzymatic solutions are becoming indispensable. Pharmabiz.world is proud to lead this revolution, offering advanced enzymes that enable sustainable, efficient, and high-quality textile production.

By embracing Pharmabiz.world’s innovations, manufacturers can not only achieve operational excellence but also contribute to a cleaner, greener future for the textile industry.

Visit our website: https://www.pharmabiz.world/textile-industry | Email Us Your Requirements: [email protected] OR Call / WhatsApp Now for Order: 01169310523.

0 notes

Text

Which are the Largest Rubber Companies in India?

India is a country which is known for its immense productions and manufacturing units. One such thing that India produces is rubbers. Rubber is a versatile material which plays a very important role in the development and operations of a range of companies.

#Grinding Machine#Packaging Industry#Paper Industry#Textile Industry#Plywood & Laminate Industry#Steel Industry#Tyre Industry

0 notes